Fiber-reinforced materials for shield segments and track plates

High-Strength Polypropylene Synthetic Macro Fiber: The Invisible Guardian of Large Shield Tunnels

Introduction: The Solid Backbone of the Infrastructure Giant China, often dubbed the "infrastructure madman," is renowned for its unparalleled scale and speed in construction. From the sprawling high-speed rail network to the intricate web of urban subways, shield tunnels and track slabs serve as the backbone of transportation and urban development. The quality and durability of these large concrete precast components directly impact project safety and longevity. High-Strength Polypropylene Synthetic Macro Fiber (High-Strength Series) has emerged as an advanced reinforcement material, acting as the invisible guardian of these century-defining projects. This article delves into its exceptional performance in shield tunnel segments, track slabs, and related applications, alongside our extensive experience in China’s infrastructure landscape.

Unique Advantages of High-Strength Fiber

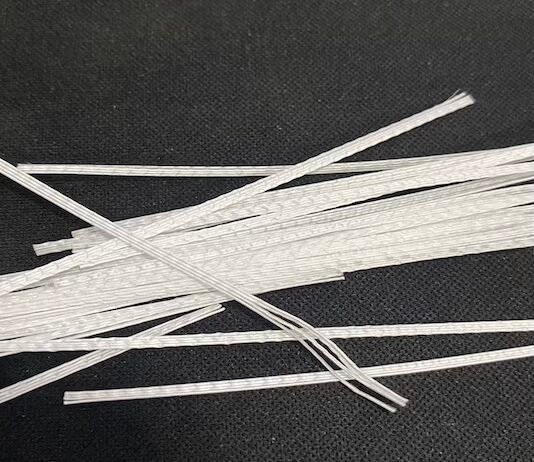

The High-Strength Series, including Twist Wave Synthetic Fiber, High-Strength Macro Synthetic Fiber Four-Strand, and High-Strength Macro Synthetic Fiber, is made from a blend of polypropylene (PP) and polyethylene (PE). With a tensile strength exceeding 600 MPa, an elastic modulus >10 GPa, and an elongation at break <8%, it showcases remarkable toughness and crack resistance. In shield tunnel segments and track slab production, its lightweight nature (density 0.91 g/cm³) and superior dispersibility significantly enhance concrete’s compressive and shear strength. The innovative design—such as Twist Wave Fiber’s three 0.3mm monofilaments with central grooves for improved bonding, and Four-Strand’s dispersion into four 0.2mm filaments during mixing for better micro-crack control—proves highly effective in tunnel reinforcement. Additionally, its low rebound rate (<5%) in shotcrete applications minimizes material waste and protects edges and corners, ensuring structural integrity.

Application Scenarios: From Tunnels to Tracks

Shield tunnel segments, critical to tunnel construction, must withstand high pressure and long-term erosion. High-strength fibers enhance crack resistance and durability through three-dimensional reinforcement, extending lifespan, particularly in coastal or high-humidity regions. Track slabs, essential for high-speed rail and metro systems, require resistance to repeated loads and high precision, where these fibers ensure stability and safety. In shotcrete, their low rebound and ease of application make them a top choice for tunnel lining and reinforcement.

Successful Practices in China’s Infrastructure Boom

In China’s infrastructure frenzy, we have contributed to landmark projects like the Beijing-Shanghai High-Speed Rail, the Hong Kong-Zhuhai-Macau Bridge, and numerous metro lines. These projects demand exceptional material performance and construction efficiency, which our high-strength fibers have met with consistent quality and excellence. From tunnels buried hundreds of meters deep to track slabs in frigid regions, we have amassed vast experience, building a skilled technical team and robust production capacity to address diverse global engineering needs.

Market Trends and Future Outlook

In 2025, global infrastructure construction is entering a new peak, driven by initiatives like the Belt and Road. Simultaneously, environmental regulations are tightening. High-strength polypropylene fibers, with their low-carbon manufacturing and high efficiency, align perfectly with these trends. Compared to traditional steel fibers, their lightweight and corrosion-resistant properties reduce transportation costs and long-term maintenance, positioning them as a green building solution.

Conclusion: The Promise of the Invisible Guardian

High-Strength Polypropylene Synthetic Macro Fiber, with its outstanding performance and broad applications, serves as the invisible guardian of large shield tunnels and track slabs. Amid China’s infrastructure triumphs, we have not only witnessed technological advancements but also demonstrated our expertise and capability. Confident in facing any challenge, we are committed to delivering high-quality solutions to global clients, co-building a safer, more sustainable future.