Environmental Macro Synthetic Fiber: The Cost-Effective Choice for General Concrete, Civil, and Municipal Engineering

In general concrete, civil, and municipal engineering projects such as roads, bridges, residential foundations, and sidewalks, fiber reinforcement has become essential for enhancing concrete performance. Our Environmental Macro Synthetic Fiber stands out for its cost-effectiveness and eco-friendly properties, making it ideal for these applications. Compared to Standard Macro Synthetic Fiber, it offers a superior balance of performance and cost, while Monofilament Fiber, the most common and widely used fiber, meets diverse engineering needs. Below, we compare these fibers’ features and advantages.

Environmental Macro Synthetic Fiber: The Eco-Friendly, Cost-Effective Choice

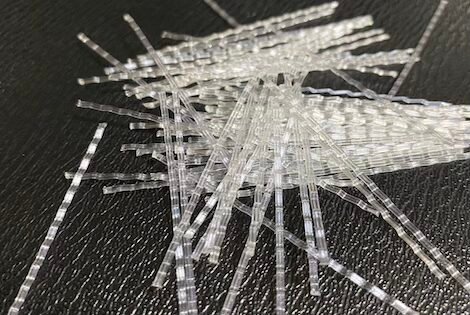

Environmental Macro Synthetic Fiber is made from recycled polypropylene (Recycled PP), combining sustainability with reliable performance for general concrete reinforcement. Its key features include:

Tensile Strength: ≥350 MPa, meeting the strength needs of general concrete.

Elastic Modulus: >5000 MPa, ensuring toughness and crack resistance.

Elongation at Break: <15%, maintaining structural stability.

Eco-Friendly: Uses recycled materials, reducing resource consumption and aligning with green building trends.

Flexible Packaging: 10kg/bag (bulk) or water-soluble bundles, facilitating construction.

Cost-Effectiveness: Lower cost than steel or high-performance fibers, with dependable performance.

This fiber is ideal for civil engineering (e.g., residential foundations, parking lots) and municipal projects (e.g., road paving, sidewalks). Its easy dispersion ensures uniform distribution in concrete, enhancing crack resistance and durability while reducing maintenance costs. For instance, in municipal road projects, Environmental Macro Synthetic Fiber minimizes pavement cracks, extending service life.

Standard Macro Synthetic Fiber: A Reliable, Standardized Option

Standard Macro Synthetic Fiber, made from pure polypropylene (Pure PP), is designed for general concrete reinforcement with consistent performance. Its features include:

Tensile Strength: ≥350 MPa, comparable to Environmental Macro Synthetic Fiber.

Elastic Modulus: >5000 MPa, enhancing concrete toughness.

Elongation at Break: <15%, ensuring stability.

Packaging Options: Transparent or water-soluble bundles, 8 tons (bulk) or 20 tons (bundles) per 40ft container.

Applications: Suitable for precast concrete, industrial flooring, and municipal projects.

Standard Macro Synthetic Fiber is widely used in bridges, tunnel linings, and precast components due to its standardized production and reliability. However, its use of virgin PP makes it slightly more expensive than Environmental Macro Synthetic Fiber, making it ideal for projects requiring high material purity.

Environmental vs. Standard Macro Synthetic Fiber: Cost-Effectiveness Comparison

For general concrete, civil, and municipal engineering, the key differences between Environmental Macro Synthetic Fiber and Standard Macro Synthetic Fiber lie in cost and sustainability:

Cost Advantage: Environmental Macro Synthetic Fiber, made from recycled materials, offers lower production costs, making it more competitive for budget-conscious projects like rural roads.

Sustainability: Its recycled PP composition reduces environmental impact, aligning with global sustainability goals and green building certifications.

Performance Comparison: Both fibers offer ≥350 MPa tensile strength and >5000 MPa elastic modulus, meeting the crack resistance and durability needs of general concrete.

Application Flexibility: Both are suitable for roads, bridges, and foundations, but Environmental Macro Synthetic Fiber excels in cost-sensitive projects, while Standard Macro Synthetic Fiber suits standardized, high-spec applications.

For example, in a municipal sidewalk project, Environmental Macro Synthetic Fiber can save approximately 15-20% in material costs while delivering comparable crack resistance to Standard Macro Synthetic Fiber, offering significant economic benefits.

Monofilament Fiber: The Most Common and Widely Used Fiber

Monofilament Fiber, the most common and widely used fiber in the market, is valued for its fine diameter and versatility in general concrete reinforcement. Its features include:

Tensile Strength: >550 MPa, providing superior strength.

Diameter: 20-30μm, ideal for controlling micro-cracks.

Elongation at Break: <30%, enhancing concrete toughness.

Packaging: 1kg/small bag, 20kg/large bag, 20 ton. s per 40ft container.

Wide Applications: Used in residential foundations, concrete slabs, and small municipal projects, though not suitable for shotcrete.

Monofilament Fiber’s low cost and ease of use make it a go-to choice for residential and small-scale civil projects, effectively controlling early micro-cracks and extending concrete lifespan.

Our Professional Commitment

我们专注于为一般混凝土、土木工程和市政工程提供经济高效的纤维解决方案。我们的环保粗纤维、标准粗纤维和单丝纤维从中国山东发货至全球客户,最低起订量 200 公斤,并提供免费样品(最多 5 公斤,运费到付)。通过严格的质量控制和创新研发,我们确保产品符合国际标准,提供耐用且经济高效的混凝土增强材料。选择我们的纤维,实现可持续性、性能和成本的完美平衡!

LATEST NEWS

What synthetic fibers are used in shield segments, track plates, and large concrete components?

IntroductionIn modern civil engineering, tunnel segments, track slabs, and large concrete components demand materials with exceptional crack resistance, durability, and

What kind of synthetic fiber is used in high performance concrete?

IntroductionUltra-high-performance concrete (UHPC) is renowned for its exceptional strength, crack resistance, and durability, widely used in bridges, tunnel linings, and